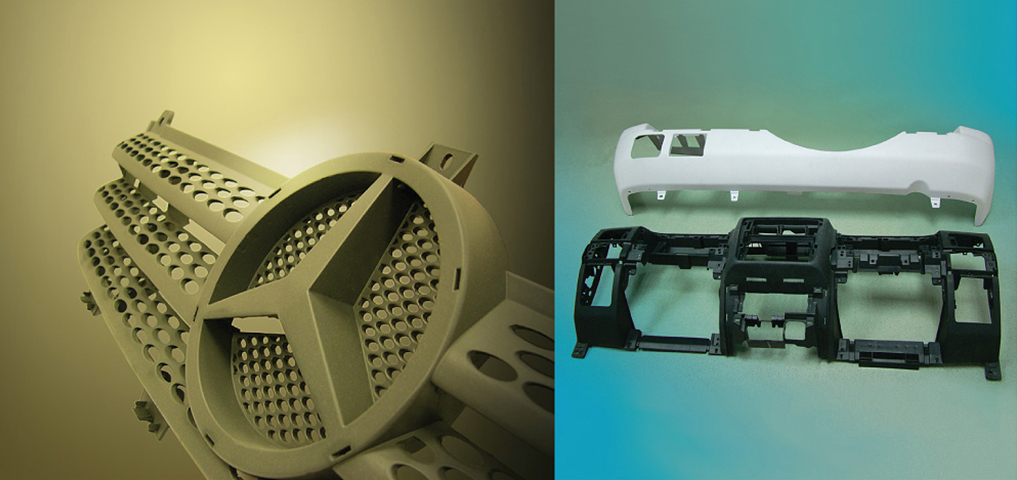

Reaction Injection Molding

Reaction Injection Molding (RIM) is similar to injection molding except thermosetting polymers are used, which requires a curing reaction to occur within the mold.

Common items made via RIM include automotive bumpers, air spoilers, and fenders.

Reaction injection molding can produce strong, flexible, lightweight parts which can easily be painted. It also has the advantage of quick cycle times compared to typical vacuum cast materials. The bi-component mixture injected into the mold has a much lower viscosity than molten thermoplastic polymers, therefore large, light-weight, and thin-walled items can be successfully RIM processed. This thinner mixture also requires less clamping forces, which leads to smaller equipment and ultimately lower capital expenditures. Another advantage of RIM processed foam is that a high-density skin is formed with a low-density core.